Aikace-aikace na Boron Carbide Foda

Boron carbidewani baƙar fata crystal ne mai ƙyalli na ƙarfe, wanda kuma aka sani da black lu'u-lu'u, wanda wani abu ne wanda ba na ƙarfe ba.Taurin boron carbide shine kawai bayan lu'u-lu'u da cubic boron nitride, kuma har yanzu yana iya kiyaye ƙarfi mai ƙarfi a babban zafin jiki, wanda za'a iya amfani dashi azaman madaidaicin abin da zai iya jurewa yanayin zafi;nauyin boron carbide yana da ƙananan ƙananan (yawan ka'idar shine kawai 2.52 g / cm3), mafi sauƙi fiye da Janar yumbura kayan za a iya amfani da su a filin sararin samaniya;boron carbide yana da karfin shanyewar Neutron mai karfi, da kwanciyar hankali mai kyau, da wurin narkewa na 2450 ° C, don haka ana amfani da shi sosai a masana'antar nukiliya.A lokaci guda kuma, ƙarfinsa na sha neutron Ana iya ƙara haɓaka ta hanyar ƙara B element;da boron carbide abu tare da takamaiman ilimin halittar jiki da tsarin kuma yana da musamman photoelectric Properties;Bugu da kari, boron carbide yana da babban narke batu, high na roba modulus, low fadada coefficient da kuma mai kyau iskar oxygen iya aiki, da dai sauransu Abvantbuwan amfãni, duk wanda ya sa ya zama m aikace-aikace abu a da yawa filayen kamar karfe, sinadaran masana'antu, inji, Aerospace da kuma aerospace. soja masana'antu.Misali, sassa masu jure lalata da lalacewa, yin sulke mai hana harsashi, sandunan sarrafa wutar lantarki da abubuwan da ake kira thermoelectric, da sauransu.

Babban aikace-aikacen boron carbide sune kamar haka:

1.Application na goge goge

Aiwatar da boron carbide a matsayin abrasive shine yafi goge sapphire.A cikin kayan aiki masu ƙarfi, taurin boron carbide ya fi naaluminum oxideda silicon carbide, kawai ƙasa da lu'u-lu'u da cubic boron nitride.Boron carbide abrasive (Mohs hardness 9.3) shine mafi kyawun abu don sarrafawa da niƙa lu'ulu'u na sapphire.Lokacin da boron carbide ya wuce 600 ℃, samansa zai zama oxidized zuwa fim din B2O3, wanda zai yi laushi da shi zuwa wani wuri.Sabili da haka, bai dace da busassun bushewa tare da zafin jiki mai yawa a cikin aikace-aikacen abrasive ba, amma kawai don goge ruwa mai niƙa.Koyaya, wannan kadarorin na iya hana ƙarin iskar shaka na B4C, wanda ke sa ya sami fa'idodi na musamman a aikace-aikacen refractory.

2.Application na refractory kayan

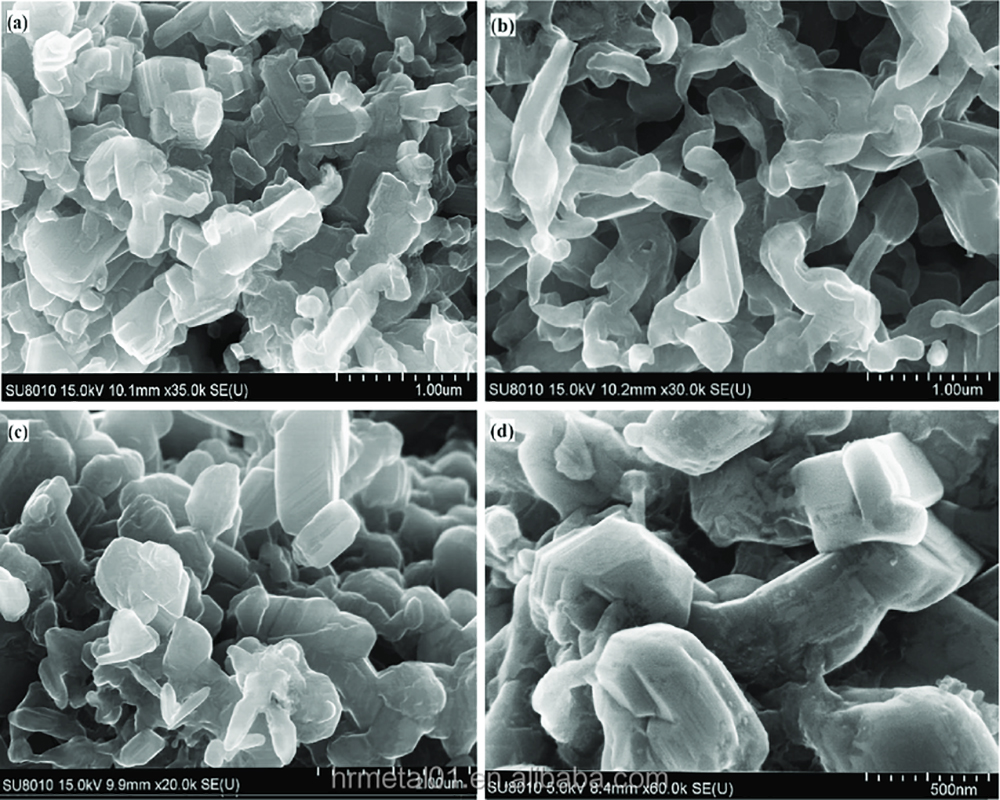

Boron carbide yana da halayen juriya na iskar shaka da juriya mai zafi.An yi amfani da shi gabaɗaya azaman ci-gaba mai siffa da amorphous refractories a fannoni daban-daban na ƙarfe, irin su murhun ƙarfe, kayan kiln, da sauransu.Ko da samfurin yana da yawa, fim din B2O3 oxide a samansa zai iya samar da wani nau'i na kariya kuma yana taka rawar anti-oxidation.A lokaci guda, saboda lu'ulu'u na columnar da aka samar ta hanyar amsawa ana rarraba su a cikin matrix da rata na refractory, porosity yana raguwa, matsakaicin matsakaicin zafin jiki yana inganta, kuma ƙarar haɓakar lu'ulu'u da aka haifar na iya warkar da raguwar girma kuma rage fasa.

3.Aikace-aikacen kayan kare harsashi

Saboda tsananin taurinsa, ƙarfinsa, ƙananan ƙayyadaddun nauyi da tsayin daka mai ƙarfi, boron carbide ya dace da yanayin kayan kariya mara nauyi, kuma shine mafi kyawun kayan hana harsashi don jirgin sama, motoci, makamai, jikin ɗan adam da sauran kariya.

4.Aikace-aikace a cikin masana'antar nukiliya

Boron carbide yana da babban sashin shayarwar neutron da kuma faffadan bakan shayarwar neutron, wanda duniya ta amince da shi a matsayin mafi kyawun abin sha a masana'antar nukiliya.Boron carbide yana da wadataccen albarkatu, juriya na lalata, kyakkyawan kwanciyar hankali na thermal, babu isotopes na rediyoaktif, ƙarancin hasken rana na biyu, da sauransu, don haka ana amfani da shi sosai azaman kayan sarrafawa da kayan kariya a cikin injinan nukiliya.Za a sanya sinadarin boron carbide ya zama sandunan boron carbide a cikin tashar makamashin nukiliya, sannan kuma za a sanya shi cikin foda na carbide na boron saboda buƙatar ƙara sararin samaniya.

Chengdu Huarui Industrial Co., Ltd.

Email: sales.sup1@cdhrmetal.com

Waya: + 86-28-86799441

Lokacin aikawa: Oktoba-08-2022